TRANSFORM YOUR EV MOTOR PRODUCTION & INNOVATION

Leverage JULI Automation's Expertise in Hairpin Winding Technology and Comprehensive R&D Services

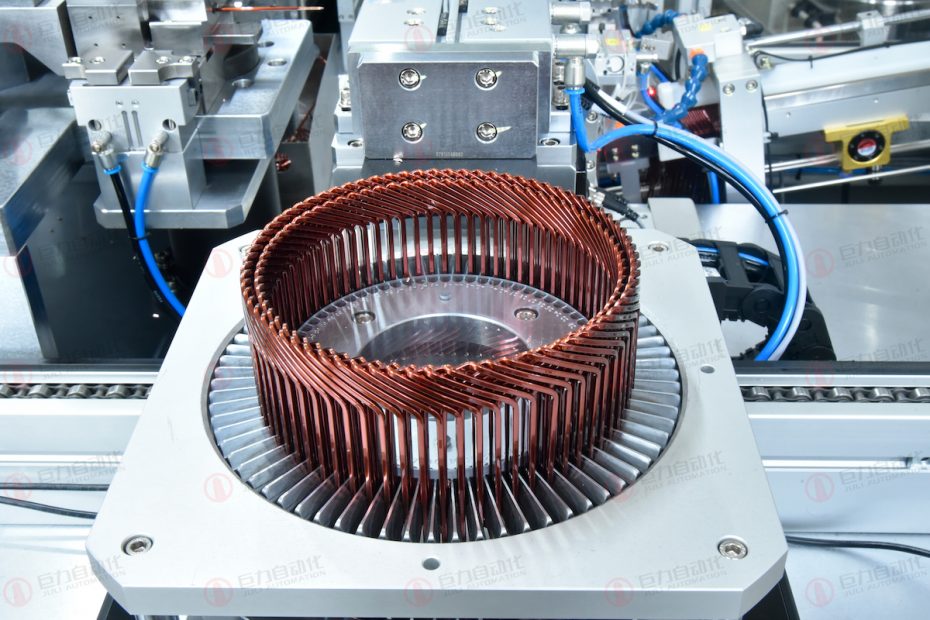

Hairpin Winding Technology:

Overcoming Challenges in Electric Vehicle Motor Manufacturing with Our Expert Hairpin Winding Solutions

At JULI Automation, our extensive experience and cutting-edge capabilities ensure your motors deliver the highest possible performance and efficiency.

Our Hairpin Winding Solutions

Stable

1. First fully automated flat wire motor mass production line in China has been delivered for 53 months of continuous and stable production

2. Trusted by customers for 34 years with over 350 production lines delivered, including over 30 EV motor mass production

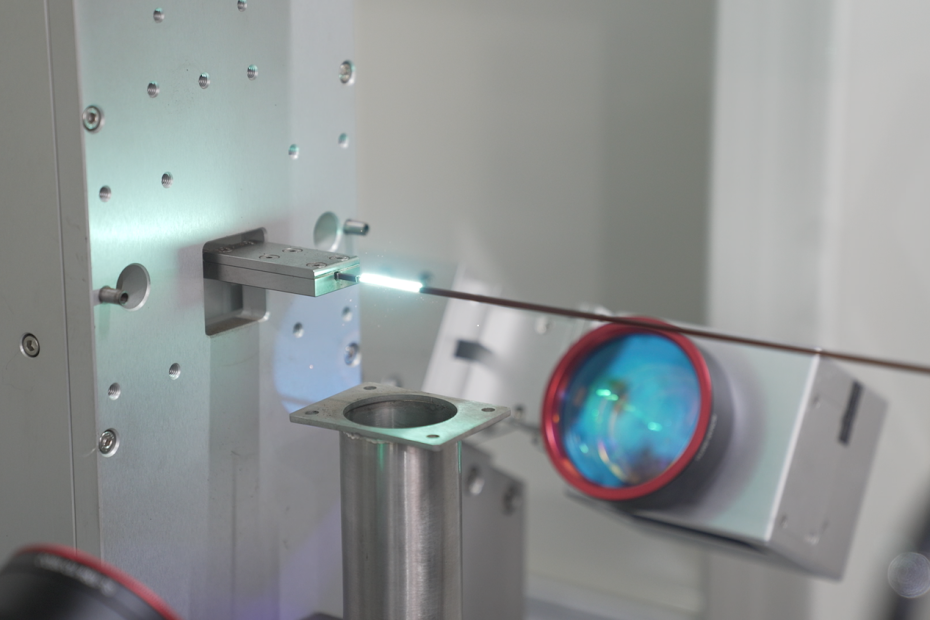

Intelligent

1. Full traceability of production and quality information

2. Mechanical simulation

3. Virtual commissioning

4. Digital twin

Efficient

1. Molding one Upin every second

2. For each CT90s production line, 2 molding machines correspond to OK

3. Complete one solder joint every 0.2 second

Advanced

1. Advanced motor technology development -X-pin

2. Focus on the future -W-pin

EV Design, Prototyping & Production

Achieve Your Electric Vehicle Goals with Our Dedicated Design, Prototyping, and Production Expertise

Consultation & Concept

What JULI Automation Can Do For You:

a. Analyze market trends and competition

b. Process feasibility analysis and verification

c. Process and equipment development

Design & Manufacturing

What JULI Automation Can Do For You:

a. Innovative process design and optimization

b. Lean manufacturing and assembly

c. Visual parameter setting and virtual debugging

Implementation & Support

What JULI Automation Can Do For You:

a. Quick response to troubleshooting

b. Reasonable inventory and parts support

c. Intimate factory delivery

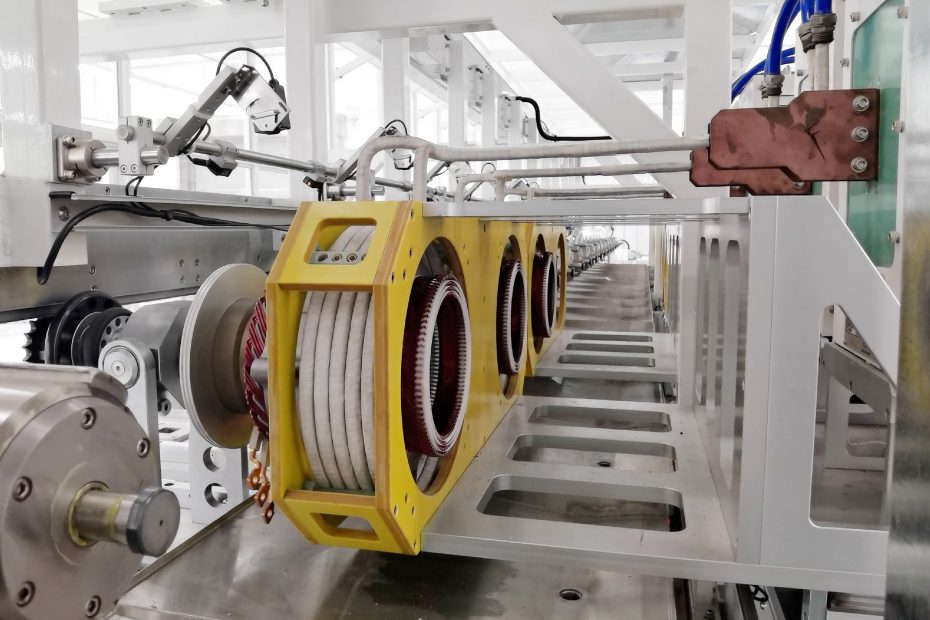

EV Motor Automated Assembly Lines

We offer automated assembly lines tailored to meet all quality, flexibility, scalability, and traceability demands. JULI Automation has established a prominent presence in the EV motor assembly sector, especially in China, where we command over 30% market share.

Over the past five years, we've perfected standard processes for each assembly stage that meets or exceeds global quality standards, letting our customers save time and money on their EV motor assembly investments.